PEST CONTROL

By Duane Grassmann

Integrated Pest Management in Food Manufacturing Facilities

An alternative to pest annihilation

Photo credit: Dejan Kolar/iStock / Getty Images Plus via Getty Images

SCROLL

DOWN

The need to protect our food resources from invading pests has been a laborious process since the beginning of humankind. Long ago, pest control practices were reactionary to specific pests, geared toward specific conditions, and not as strategic as practices used today.

Even into the 1970s, ’80s, and ’90s, eradication was the primary response to pest-related issues. Fortunately, cooler heads began to understand that managing pests through control strategies, rather than annihilation, was the key to success. Thus, integrated pest management (IPM), as the new approach was known, began to develop into today’s strategies.

In some instances, food manufacturing companies, including their warehouses and distribution centers, have chosen to utilize internal personnel to manage all aspects of their IPM programs. More commonly today, each facility manages their IPM program with the assistance of a contracted pest management provider. In both cases, there is at least one pest management professional (PMP) who is assigned to each facility’s IPM program and works with the facility team.

This article will discuss the differences between pest control and IPM, the common strategies of robust IPM programs, common pitfalls in IPM programs, and pesticides. The goal is to help facilities improve their understanding of “the why behind the what” regarding IPM strategies, to share some best practices, and to draw attention to common IPM pitfalls.

Pest Control or IPM?

What is the difference between a pest control program and an IPM program of control?

Some facilities may operate a pest control program as opposed to an IPM program because they take the approach of “see a bug, kill a bug.” They have a generally reactive posture toward pests. Additionally, these facilities have often incrementally shifted ownership of the program to the contracted PMP. These facilities are easily identified through their heavy reliance on pesticides as well as high catch rates for rodents and insects. To the keen eye of a professional upon approaching the property, many visuals will point to their program. If the facility’s focus is strictly pest control, there can be accumulations of leaves and trash around the building, poor storage practices, trees and shrubs growing against the building, tall grass, and standing water long after the last rain. Once inside the building, one can spot poor housekeeping, inadequate building maintenance, and poorly maintained pest management devices. Dead insects in multiple light covers and dark, dust-covered cobwebs in warehouses are also some of the easy-to-spot indicators.

Facilities that operate a robust IPM program have the attitude that taking a holistic approach to pest prevention pays greater dividends than solely reacting to pests when they appear. They own the IPM program and are in partnership with the PMP. These facilities embrace and utilize strategies and programs that:

- Have multiple layers of protection to keep pests away from the property, out of the building, and away from the sensitive areas inside the facility

- Ensure everyone (facility personnel, contractors, and visitors) knows their role in IPM

Integrated Approaches for a Robust IPM Program

The main strategies of an IPM program are to:

- Exclude pests from food manufacturing and storage facilities by effective and well-maintained physical and alternate barriers

- Restrict pests by denying them food, water, harborage, controlled temperature, and/or oxygen

- Control pests by removal of harborage in grounds and around the building, and removal of infested materials

When intentionally and intelligently executed within an integrated approach to pest management, these programs reduce contamination of food by pests and minimize the use of pesticides. Let’s look closer at these strategies.

“Long ago, pest control practices were reactionary to specific pests, geared toward specific conditions, and not as strategic as practices used today.”

Exclude and restrict pests by eliminating primarily food and water as well as harborages on the property and around the building:

- Care for lawn and shrubs, keeping foliage off the ground and well away from the building

- Choose (or avoid) certain types of trees and shrubs—consult an arborist for non-pest attracting types

- Exterior lighting (type and location) should exclude mercury vapor and fluorescent lamps as they attract flying insects; should not be mounted to the building exterior because this attracts insects to the building; should be located away from the building and project toward the building, as insects attracted to the bulbs will be away from the building and its doors and windows

- Use good storage practices outside the building; miscellaneous items stored outside, such as pipes, pallets, idle equipment, etc., should be off the ground and well away from the building

- Eliminate and prevent accumulation of trash and debris, including brush and leaves

- Ensure adequate drainage to eliminate standing water

- Ensure good cleaning and storage practices around the trash compactor

- Establish and maintain rodent barriers (not bait stations) around the fence and property lines and around the building; typically, this is crushed rock or cement, 18–36 inches across by 6 inches deep that is kept free of vegetation, including weeds and grass

- Conduct scheduled, well-documented inspections

Exclude and control pests by maintaining the building exterior and roof:

- Eliminate standing water and food residues on the roof

- Seal cracks, penetrations, and holes into the building

- Ensure doors and windows are tightly sealed

- Windows that can be opened must have intact and appropriate mesh screens (16- to 20-gauge mesh)

- Install or maintain screens or louvers on vents and exhaust ducts

- Ensure there are no gaps around loading dock doors and leveler plates; consider attaching metal plating to exterior walls below dock door levelers as rodents can climb cement and enter the leveler area

- Eliminate or add deterrence to locations where birds can roost and nest

- Conduct scheduled, well-documented inspections

Exclude, restrict, and control pests by maintaining the interior of the building through established procedures, well-managed building structures, and sanitary conditions:

- Promptly clean up spills and maintain excellent housekeeping, especially in storage areas

- Maintain good storage practices by keeping equipment and supplies off the floor, maintaining storage area inspection lines (painted white on the floor, 18 inches from perimeter walls and posts, frequently cleaned and inspected) and using a first in/first out (FIFO) and first expired/first out (FEFO) inventory rotation (a single pallet of old ingredients in a warehouse can cause significant pest opportunities)

- Identify and eliminate pest harborages

- Inspect incoming and outbound trailers and materials

- Maintain positive room air pressure in the most sensitive areas and progressively lower pressures to less sensitive areas, with the lowest pressure outside the building to keep flying insects from being pulled into more sensitive areas

- Ensure exhaust vents in ceiling and walls have functioning closures, louvers, and/or screens

- Ensure effective air curtains, well-sealed doors and windows, and appropriate window screens are in place and functioning properly

- Conduct scheduled, well-documented inspections

IPM Devices and Layers of Protection

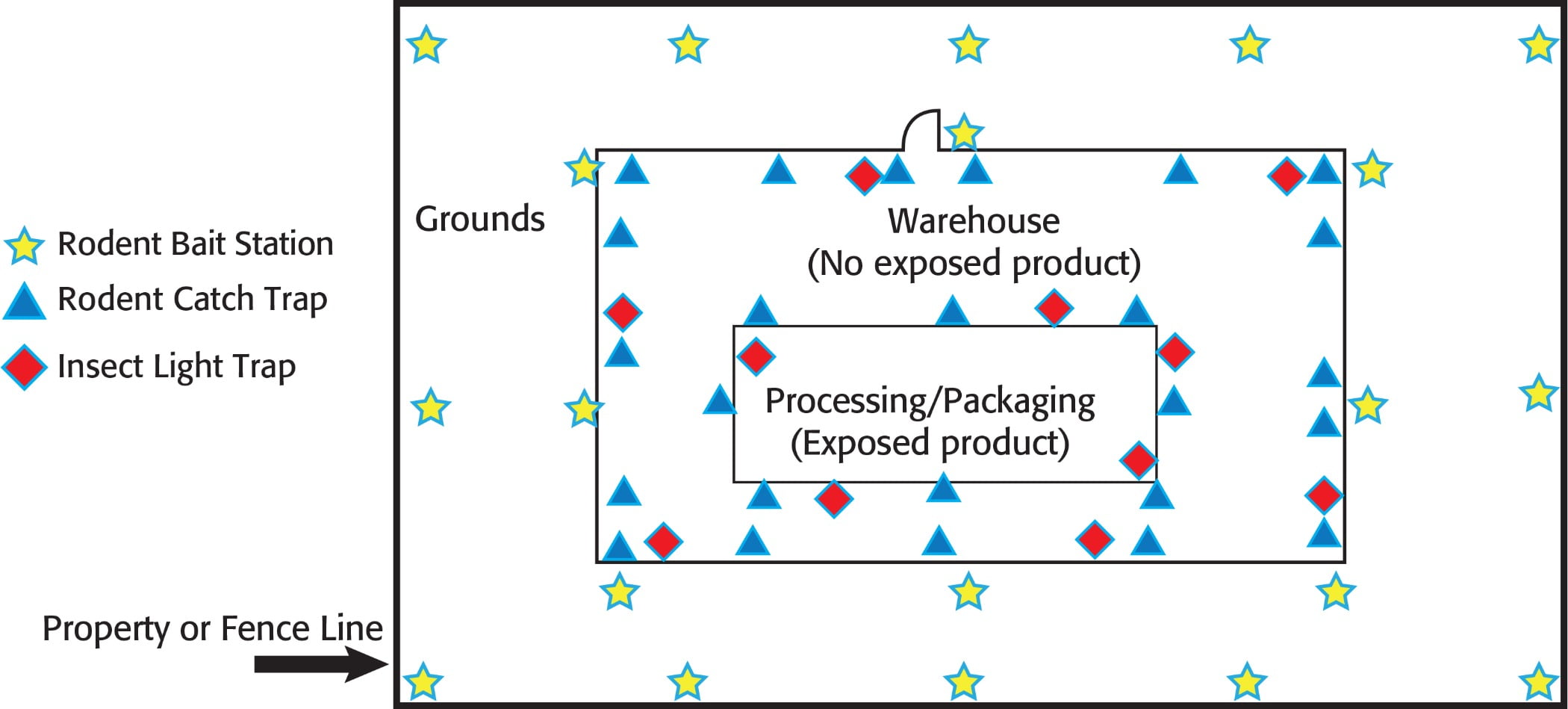

Rodent control programs often, but not always, take the form referred to in Figure 1:

- An exterior perimeter of locked and secured rodent bait stations (serviced with a rodenticide or placebo referred to as a nontoxic bait per current local regulation)

- A second layer of locked and secured bait stations around the exterior of the building(s) in which toxic baits may be used per local regulation

- An interior positioning of a nonbaited rodent catch-trap perimeter around the inside of exterior walls as well as on both sides of exterior doors and loading dock doors (details of the layout or mapping will depend on entry points)

- An additional layout should be considered around ingredient storage areas or possibly processing/packaging areas (this depends upon your inspections and data trending)

For insects, the layered approach is also employed, where light traps are placed at strategic locations within the facility (Figure 1). Please keep in mind that certain exterior lights, as well as insect light traps (ILTs), can attract insects from tremendous distances. Therefore, placement and types of light are critical. Do not utilize ILTs on the exterior of the facility as these will attract insects to the property, building, windows, and doors. Here are common layers of insect protection from ILTs:

- Install insect light traps inside the building near all exterior doors and loading docks; ensure light from these ILTs is not directed at a door and not easily seen from the outside

- Install ILTs on the outside walls of sensitive areas within the facility (inspections and data trends will assist in placement decisions)

- Install ILTs on the inside of sensitive areas within the facility; ensure light from these ILTs is not visible from outside the sensitive area

- Exterior lighting should not attract insects to the building or its entrances; consult a reputable contracted IPM provider/contractor when deciding on lighting types and locations

Here are some additional thoughts about IPM devices with focus on risk-based prevention:

- Distances between rodent bait stations and rodent catch traps should be designed to the need of the facility and the environment

- Rodent catch and feeding activity, available harborage, attractants, and other conditions may dictate even closer placement of devices

- Placement of devices should change as conditions dictate and root cause of pest presence is eliminated; temporary devices can also be used provided device maps are updated

- All devices, as well as their physical location, must be numbered and be depicted on accurate, up-to-date maps

- Pheromone traps may be viable for specific insects; please consult a reputable contracted IPM provider/contractor for more information

FIGURE 1. Sample Blueprint of a Rodent Control Program

Everyone Plays a Role in IPM

Everyone who works in a food facility can either directly or indirectly participate in an IPM, and the most effective IPM programs are those in which everyone is aware of their role. At a minimum, this starts with new-hire orientation and then annual refresher training on IPM. A reputable IPM provider/contactor can supply this training to the facility, and this training should be in your contract key performance indicators. Unfortunately, not many associates remember this training for the other 364 days in a year. Like all effective training, reinforcement must be incorporated into everyone’s daily activities. A successful IPM program includes frequent reminders to associates that they are controlling pests when they:

- Keep work areas clean and organized and promptly clean up spills

- Store items away from the walls and off the floor

- Inspect incoming trailers and goods for pests

- Rotate stock—FIFO/FEFO

- Don’t let trash or food product accumulate inside or outside the building

- Eat only in designated areas

- Keep doors closed and report torn or missing window screens

- Have rodent control devices on both sides of all outside doors and along selected walls

- Put rodent control devices back in place if they are moved during cleaning or daily operations

- Utilize protective covers for devices located in high forklift-travel areas to minimize damage

- Don’t unplug the insect light traps

- Periodically clean and inspect lockers

- Report pest sightings

- Keep the lawn, trees, and shrubs trimmed

- Pay close attention to training and monitoring of employees, contractors, and visitors for behaviors that could lead to pest infestations

- Conduct very specific inspections that include all exclusion/control elements of IPM

Common Pitfalls in IPM Programs

IPM has been around for quite a while. When it’s executed well, there are few pest problems. Consequently, facilities sometimes take it for granted or get distracted and lose focus. These facilities can fall victim to the following pitfalls:

- Allowing the IPM program to run on autopilot—when left on its own, performance seldom improves

- Not meeting with the PMP before and after each service visit to review reports, findings, etc.

- Not having a qualified backup liaison to meet with the PMP when the primary contact is not present

- Allowing PMP-requested corrective actions to remain open for excessive time; “I sent an email” is usually a lousy corrective action

- Allowing the PMP to develop tunnel vision and focus only on checking devices, ignoring the rest of the facility

- Not accompanying the PMP on their service visits at an appropriate frequency

- Reliance on pesticides instead of excluding, restricting, and controlling pests as discussed above

- Inaccuracies in pesticide application documentation such as transposed U.S. Environmental Protection Agency registration numbers, wrong date, wrong quantity used, etc.

- Losing focus on peripheral areas like the lunchroom, locker rooms, roof, and grounds

- Pesticide labels and safety data sheets as well as device maps being out of date or not being periodically reviewed

- Not providing adequate and meaningful associate training

- Accepting as normal what could be considered excessive levels of pest activity

- Failure to truly partner and calibrate expectations with the PMP

If you want to improve your facility’s IPM program, self-assessing against these pitfalls is a great place to start.

Pesticides

This section provides an overview of pesticide selection and application that may provide some insight and value. For all details regarding pesticides, always refer to the product label, the applicable regulatory agencies, your facility quality system, your IPM provider, and your customer requirements as well as other internal and external stakeholders for specific regulations, requirements, and guidelines.

Pesticide applications are one part of the IPM toolkit, but they should not be considered a first resort for maintaining an effective IPM program. Rather, they should be a last resort and utilized only as an assist in the eradication of existing pest populations to bring them to a manageable level wherein exclusion, restriction, and control become effective. Their use should not be an alternative to the IPM approaches discussed above.

Businesses and facilities should carefully identify and control which pesticides are used. This control can be easily managed utilizing a master approved pesticide list (MAPL). This MAPL should be formulated by the facility in conjunction with its IPM provider. It becomes especially important for management of commodity tolerance levels as well as compliance with “organic” and “natural” label claims. In addition, an approval procedure should be in place to vet whether a pesticide that is not on the MAPL may be used in temporary and exceptional situations. A company/facility would also be wise to have a risk assessment procedure to follow in the unlikely event that a nonapproved pesticide is found to have been applied.

How is an MAPL created? Many criteria need consideration and consultation. Among the most relevant are:

- The approved pesticides must not negatively impact

- Product integrity

Employee, customer, or consumer health

- Valuable input from the pest management provider

- Compliant with current local regulations and restrictions

- Current international restrictions may be applicable for import/export

- Current applicable international research and resulting restrictions

- Pesticide availability

- Pesticide categories

Targeted pests (e.g., bird, rodent, insect, flies) and various herbicides

Residual versus contact

Application methods (e.g., crack/crevice, space applications, fumigants, contact, broadcast, etc.)

- Specific pesticides for the types of pest likely to be encountered based on products(s) manufactured, raw materials used, and history as well as the local conditions and climate

- Limiting the number of pesticides to two or three for each targeted pest and application method

Remember, the pesticide label dictates its conditions for use.

A final thought came to mind as I wrote this article. I went camping 40 years ago with my brother and his wife in northern Minnesota. Our camping supply outfitter instructed us to hang our food packs up in the trees to keep bears from getting into them. The outfitter said bears are cowards and that if we found them trying to get to the packs, we should just throw stones at them to chase them away. Fortunately, we saw no bears, and it was never demonstrated that I was far more cowardly than they were. Rather, I was quite willing to sacrifice the food packs to the bears or to deer, squirrels, or any other critters with more than two legs. My “bear plan” was to just run faster than either my brother or his wife. In retrospect, the outfitter had suggested a very primitive form of pest control. It was shortsighted, focused on limited circumstances, based on questionable pest knowledge, and a terrible strategy at its core (seriously, throwing stones at bears?). Even four decades ago, this was a foolish pest management approach and certainly nothing like the much more enlightened, integrated approaches we have today in modern food manufacturing facilities.

Today’s food manufacturing facilities, warehouses, and distribution centers have integrated approaches to pest management, and everyone associated with these operations should understand their role. The main strategies are to exclude, restrict, and control pests. The facility owns the IPM program and works in partnership with the contracted IPM provider/contractors to get the greatest return on its investment. When necessary to regain control over pests, thoroughly document and judiciously use only approved pesticides. When pesticides must be applied, they are only applied in accordance with applicable regulations and always as directed by the product label. Rather than follow the pest control strategy of “see a bug, kill a bug,” an IPM program proactively addresses all the conditions for the pest attraction, entry, and harborage.

Duane Grassmann is a corporate hygienist, Nestlé USA & Canada.