Reducing Environmental Friction with High-Performance Coatings

Mobility, energy and general engineering operations benefit from lower energy consumption, reduced CO₂ emissions and longer equipment operating life

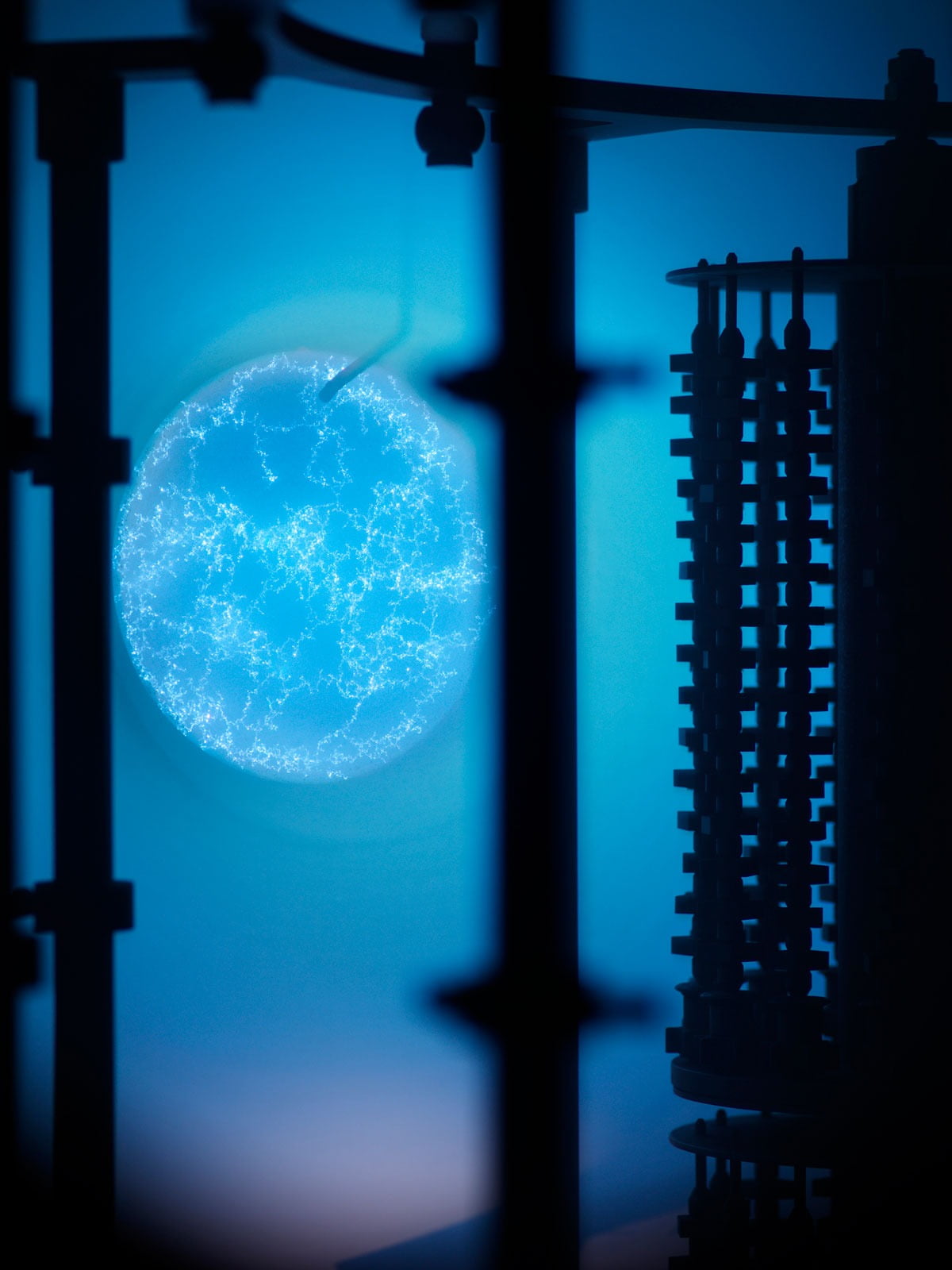

Photo courtesy of Oerlikon Balzers.

By Stephen Armstrong, Freelance Writer, Tustin, CA

Specialized physical vapor deposition (PVD) coatings are widely recognized for the critical role they perform in enhancing operational performance and extending the life of parts across countless manufacturing and industrial sectors. Less understood is the value that these coatings provide in reducing the environmental impact of the industrial processes where they are used.

It starts with one of the primary reasons to use PVD coatings in the first place, which is to reduce friction between mated parts to improve performance. This can result in direct energy savings and, by extension, reduced CO₂ emissions. Because these coatings extend the life of component parts that require frequent replacement, the raw materials, metals and energy that are required to manufacture a replacement part are also saved.

In fact, some specialized coatings manufacturers are making a strong case that coatings are a significant contributor to improving the environment. They not only point to these environmental benefits, but also to the enhancements they have made in their own coating equipment to operate more efficiently. In addition, continued advancements in specialized PVD coatings are also playing an important role in the design of components for new and emerging green technologies.

Reducing Friction with Specialized Coatings

Reducing friction when mated components are in contact with each other is critical, particularly in punishing environments where there are high loads and high wear. Bearings, gears, rollers and other precision components suffer from excessive wear, surface fatigue, pitting, galling and corrosion, which can also cause failure, especially in high-load applications.

To prevent these issues from occurring, specialized PVD coatings are applied in thicknesses of typically only a few micrometers to further harden the surface of these parts, and through mechanisms such as altering the surface chemistry they can also lower the coefficient of friction. As a result, less energy is used and fewer emissions are generated.

Carbon-based coatings such as diamond-like carbon (DLC) coatings from specialized coatings formulators are even more durable. Produced mainly through plasma-assisted chemical vapor deposition (PACVD), these well adhering coatings provide a unique combination of high hardness and low friction coefficients.

Such coated components are utilized for a variety of applications including wind turbine shaft bearings and planetary gears, stainless steel cutting blades and piston pumps, and sliding components across many industries. The coatings are also a proven technique for upgrading critical rotating parts in hydraulic drives, pumps and valves.

Advanced, hydrogen-free DLC coatings provide even higher hardness along with a very low coefficient of friction. These coatings can be applied in the most demanding environments for high friction, wear and contact areas such as in hydraulic pump parts, mechanical seals and high-pressure valve components. Today, they are also playing an increasingly important role in e-mobility applications.

Photo courtesy of Oerlikon Balzers.

Small Efficiencies Add Up

Even small percentage gains in energy savings can really add up in large-scale industrial environments. “Consider that a single percent gain in efficiency for a 200-megawatt gas turbine represents the equivalent power needed for 1,500 homes,” said Alessandro Zedda at Oerlikon Balzers.

Seemingly minor factors such as a smoother surface finish can improve fuel efficiency. In the aerospace and energy sectors, for example, PVD erosion coatings are applied to compressor blades to protect polished surfaces from degrading over time. This can reduce fuel usage by up to 0.5% while promoting component longevity. These fuel reductions translate into comparable CO₂ reductions.

Similarly, in the automotive sector, DLC-coated valve and power train components can reduce the friction mean effective pressure (FMEP) by 10%. This translates to a 2% reduction in fuel. A 20% reduction in FMEP will generate a 5% fuel consumption reduction.

More stringent environmental regulations and standards worldwide are also causing industry to focus on reducing their carbon footprint and design greener products.

Photo courtesy of Oerlikon Balzers.

Take large cargo ships as an example. Today, operators need to reduce the sulfur content of their fuel in order to be compliant with current sulfur cap requirements. With a cleaner fuel mandate, marine engine manufacturers require a new fuel injection technology because clean fuels typically do not lubricate as effectively as those with a higher sulfur content.

As a result, the coatings used in diesel marine engines also needed to be redesigned to ensure the new clean fuels will work well. Coatings that meet this new requirement have become an enabler of more efficient, higher performance, cleaner and smoother running machinery.

Extending the Life of Parts Saves Energy

The environmental benefit of high-performance coatings is also realized by how they extend the life of parts and tools. When parts last longer they are replaced less frequently, which reduces the raw materials, metals and energy it takes to manufacture them.

In the automotive sector, forming tools are made from multi-ton pieces of steel in the negative shape of a car. Used to make millions of cars, the forming tools will degrade over time and require reworking. To ensure optimal performance and long life, they require polishing and a PVD coating application. In addition to saving energy by keeping the forming tool in optimal condition, additional energy is saved by less frequently moving equipment of this size and weight to a separate location to be repaired.

In the energy sector, applying a DLC coating to roller bearings in wind turbines extends their life and lowers maintenance expenses. Consider that changing one main shaft bearing costs between $200-$300,000 in addition to the disruption caused by taking the turbine off the grid.

Enabling Green Technology Development

Beyond improving the efficiency and carbon emissions of existing systems, PVD coatings can be an enabler of new green technologies in categories such as fuel cells and high-power energy density batteries.

“Within the fuel cell sector, we are working with a client who manufactures bipolar plates, a key component in fuel cells,” said Alessandro. “Here the role for a PVD coating will be to promote conductivity while at the same time resisting corrosion. Together these attributes will promote the longevity of the fuel cells extending their environmental benefits.”

Alessandro adds, “We are also working with clients to apply PVD coatings on some exciting and highly innovative projects in high-power energy density batteries. As industry continues to develop environmentally friendly innovations, there will be more opportunities for coatings to be engineered to support their performance and overall life span.”

Efficiencies in Coating Application Generate an Environmental ROI

Further up the specialized coatings supply chain, coatings manufacturers themselves have examined their processes for applying coatings since it consumes both materials and energy.

When the energy consumed to produce coatings is compared to the energy savings they generated in their application, either through the improved efficiency and longevity of an engine or a cutting tool, an ‘energy payback’ or return on investment is generated.

“We are constantly striving to reduce the energy consumption of our coating equipment,” said Alessandro. “Our new coaters consume 40% less energy by using new, more efficient plasma sources. Multiply this saving on every batch at all our coating centers around the world and the environmental benefit is huge.” He adds, “While the impetus to explore a new source was environmentally driven, it is also in our customers’ economic best interests because it reduces their coating cost and shortens our manufacturing cycle.”

Specialized coatings have an important role to play in reducing our environmental impact. Energy consumption and carbon emissions of manufacturing and operations processes can be reduced significantly. So, while industry continues to use specialized coatings for their ability to enhance operating performance, the environmental impact is an important value-add that should not to be overlooked.

For more information about coating solutions for components with Oerlikon Balzers e-mail: balzers.components@oerlikon.com; or visit www.oerlikon.com/balzers.