By Austin Weber, Senior Editor

Gyroscopes: An Old Technology Behind New-Age Vehicles

AV/EV Tech Trends

“Most smartphones contain gyroscopes to detect the orientation of the screen and help figure out which way we’re facing, but their accuracy is poor,” adds Jae Yoong Cho, Ph.D., an assistant research scientist in electrical engineering and computer science.

“They’re the reason why phones often incorrectly indicate which direction a user is facing during navigation,” says Cho. “It doesn’t matter much to a human on the street or behind the wheel, but a driverless car could get lost quickly with a loss of GPS signal.”

The device that enables navigation without a consistent orienting signal is called an inertial measurement unit (IMU). It’s made up of three accelerometers and three gyroscopes, one for each axis in space. But, getting a good read on which way you’re going with existing IMUs is so pricey that it has been out of range, even for equipment as expensive as autonomous vehicles.

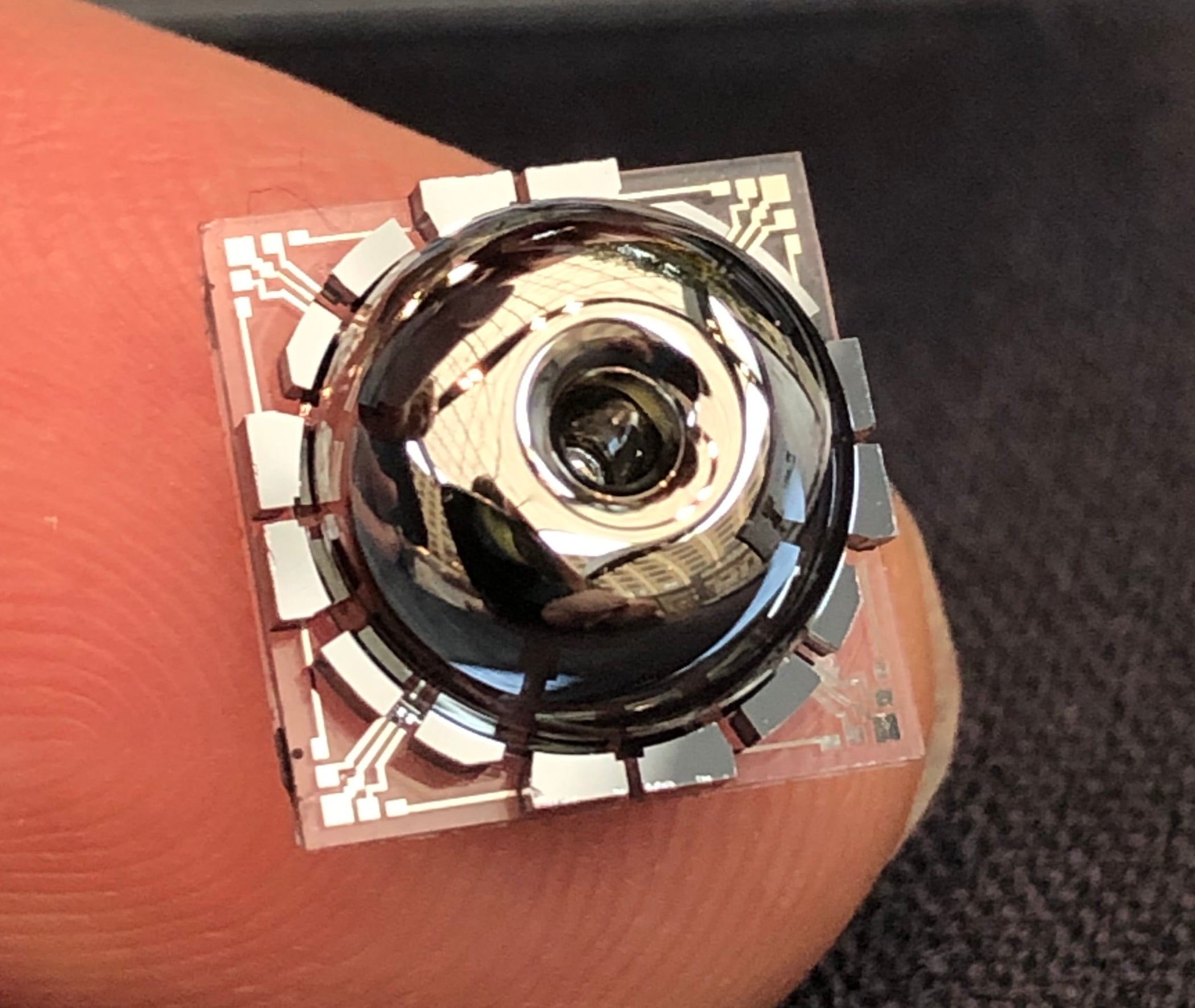

“The key to making this affordable, small gyroscope is a nearly symmetrical mechanical resonator,” explains Najafi. “It looks like a Bundt pan crossed with a wine glass, made 1 centimeter wide.

“As with wine glasses, the duration of the ringing tone produced when the glass is struck depends on the quality of the glass,” Najafi points out. “But, instead of being an aesthetic feature, the ring is crucial to the gyroscope’s function. The complete device uses electrodes placed around the glass resonator to push and pull on the glass, making it ring and keeping it going.

“Basically, the glass resonator vibrates in a certain pattern,” adds Najafi. “If you suddenly rotate it, the vibrating pattern wants to stay in its original orientation. So, by monitoring the vibration pattern, it is possible to directly measure rotation rate and angle.”

The way that the vibrating motion moves through the glass reveals when, how fast and by how much the gyroscope spins in space. The process for making the gyroscope was developed in the Lurie Nanofabrication Facility at the University of Michigan, with research supported by the Defense Advanced Research Projects Agency.

To make the resonators as perfect as possible, Najafi and his colleagues start with a nearly perfect sheet of pure glass, known as fused-silica, about 0.25-millimeter thick. They use a blowtorch to heat the glass and then mold it into a Bundt-like shape known as a “birdbath” resonator since it also resembles an upside-down birdbath. Then, they add a metallic coating to the shell and place electrodes around it that initiate and measure vibrations in the glass.

“The whole thing is encased in a vacuum package, about the footprint of a postage stamp and half a centimeter tall, which prevents air from quickly damping out the vibrations,” explains Najafi.

Cho and Najafi recently formed a startup company called Enertia Microsystems Inc. that has licensed the technology from the University of Michigan.

Inside their backup navigation systems, autonomous vehicles currently use high-performance gyroscopes that are large and expensive. But, a small, inexpensive and highly accurate gyroscope recently developed at the University of Michigan could help next-generation driverless cars, planes, ships, trucks and tractors stay on track without a GPS signal.

“Our gyroscope is 10,000 times more accurate, but only 10 times more expensive than gyroscopes used in your typical cell phone,” says Khalil Najafi, Ph.D., a professor of electrical engineering and computer science at the University of Michigan. “[It] is 1,000 times less expensive than much larger gyroscopes with similar performance.

“High-performance gyroscopes are a bottleneck, and they have been for a long time,” explains Najafi. “[Our] gyroscope can remove this bottleneck by enabling the use of high-precision and low-cost inertial navigation in autonomous vehicles.”

A small, inexpensive and highly accurate gyroscope features a symmetrical resonator made of glass. That enables it to vibrate for long periods, similar to the ringing of a wine glass. Photo courtesy University of Michigan

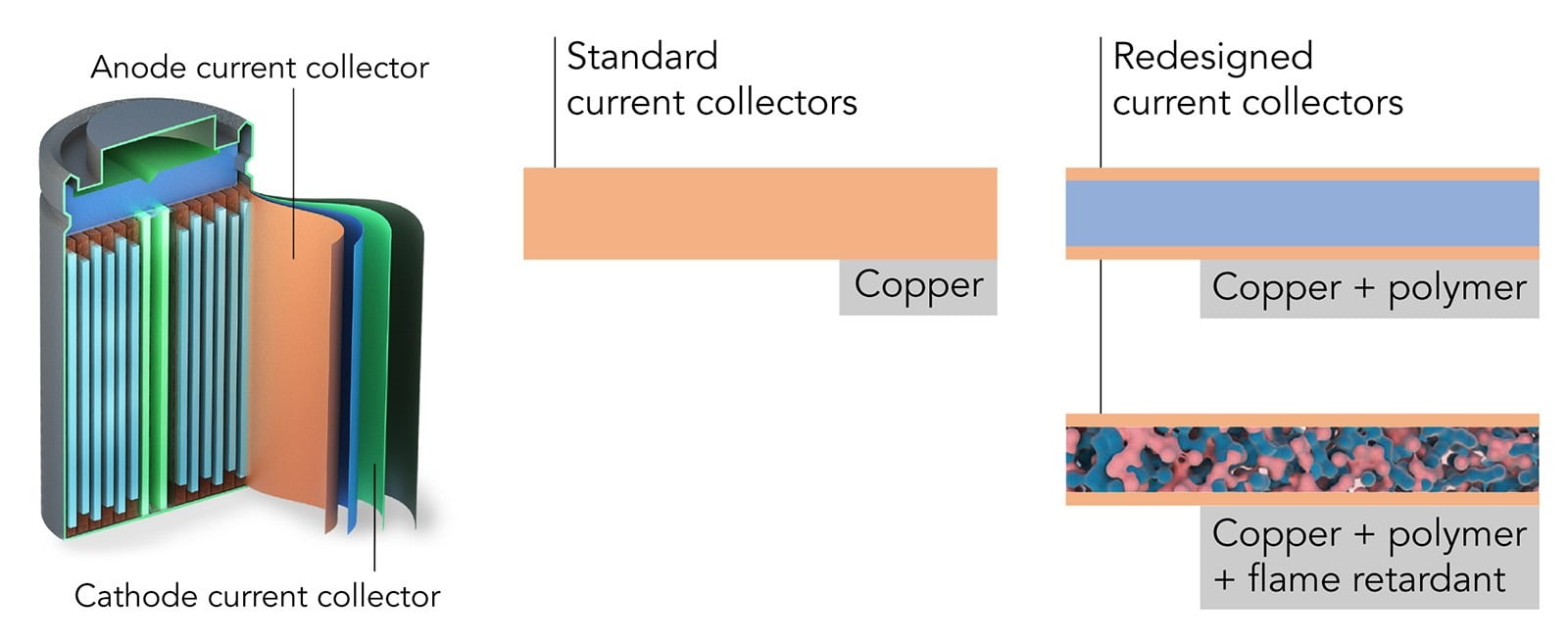

Whether they come in the form of cylinders or pouches, lithium-ion batteries have two current collectors, one for each electrode. They distribute current flowing in or out of the electrode, and account for 15 percent to 50 percent of the weight of some high-power or ultrathin batteries.

Shaving battery weight and storing more energy could enable EVs to go longer between charges. Reducing battery weight and flammability could also have a big impact on recycling by making the transportation of recycled batteries less expensive.

“Researchers have been trying to reduce the weight of current collectors by making them thinner or more porous, but these attempts have had unwanted side effects, such as making batteries more fragile, chemically unstable or requiring more electrolyte, which raises the cost,” says Cui. “People have also tried adding fire retardant to the battery electrolyte, but you can only add so much before it becomes viscous and no longer conducts ions well.”

Cui and his colleagues developed current collectors based on polyimide, a lightweight polymer that resists fire and stands up to the high temperatures created by fast battery charging. Triphenyl phosphate, a fire retardant, was embedded in the polymer, which was then coated on both surfaces with an ultrathin layer of copper. The copper would not only do its usual job of distributing current, but also protect the polymer and its fire retardant.

“Those changes reduced the weight of the current collector by 80 percent compared to today’s versions, which translates to an energy density increase of 16 percent to 26 percent in various types of batteries, and it conducts current just as well as regular collectors with no degradation,” claims Cui.

“When exposed to an open flame from a lighter, pouch batteries made with today’s commercial current collectors caught fire and burned vigorously until all the electrolyte burned away,” explains Cui. “But, in batteries with the new flame-retardant collectors, the fire never really got going, producing very weak flames that went out within a few seconds, and did not flare up again even when [we] tried to relight it.

“One of the big advantages of this approach is that the new collector should be easy to manufacture and also cheaper, because it replaces some of the copper with an inexpensive polymer,” adds Cui. “So, scaling it up for commercial production should be very doable.”

Current Collectors Boost Lithium-Ion Battery Efficiency

Engineers at Stanford University and the Department of Energy’s SLAC National Accelerator Laboratory have developed an entirely new approach to making lithium-ion batteries. Adding polymers and fireproofing to a battery’s current collectors makes it lighter, safer and about 20 percent more efficient.

One of the heaviest battery components—sheets of copper or aluminum foil known as current collectors—were re-engineered so they weigh 80 percent less and immediately quench any fires that flare up. If adopted, this technology could extend the operating range of electric vehicles.

“The current collector has always been considered dead weight, and until now it hasn’t been successfully exploited to increase battery performance,” says Yi Cui, Ph.D., a professor of material science and engineering at Stanford who led the research project.

“But, in our study, making the collector 80 percent lighter increased the energy density of lithium-ion batteries by 16 percent to 26 percent,” explains Cui. “That’s a big jump compared to the average 3 percent increase achieved in recent years.”

Stanford engineers replaced the all-copper conductor (middle) in a battery with a layer of lightweight polymer coated in ultrathin copper (top right) and embedded fire retardant in the polymer layer to quench flames (bottom right). Illustration courtesy Stanford University

Underwater Navigation System Is Powered by Sound

GPS isn’t waterproof. The navigation system depends on radio waves, which break down rapidly in liquids, including seawater. To track unmanned underwater vehicles, engineers typically rely on acoustic signaling. However, devices that generate and send sound usually require bulky batteries that require frequent changing.

Engineers at the Massachusetts Institute of Technology (MIT) have developed a battery-free pinpointing system dubbed underwater backscatter localization (UBL). Rather than emitting its own acoustic signals, UBL reflects modulated signals from its environment. That provides positioning information at net-zero energy.

“Because radio waves quickly deteriorate as they move through water, subsea communications often depend on acoustic signals instead,” says Fadel Adib, Ph.D., an associate professor of electrical engineering and computer science at MIT. “Sound waves travel faster and further underwater than through air, making them an efficient way to send data. But, there’s a drawback.

“Sound is power-hungry,” explains Adib. “For tracking devices that produce acoustic signals, their batteries can drain very quickly. That makes it hard to precisely track objects or animals for a long time-span.”

Adib and his colleagues turned to a unique resource they had previously used for low-power acoustic signaling: piezoelectric materials that generate their own electric charge in response to mechanical stress, like getting pinged by vibrating soundwaves.

Piezoelectric sensors can then use that charge to selectively reflect some soundwaves back into their environment. A receiver translates that sequence of reflections, called backscatter, into a pattern of ones (for soundwaves reflected) and zeros (for soundwaves not reflected).

“In principle, the same technology could provide location information,” says Adib. “An observation unit could emit a soundwave, then clock how long it takes that soundwave to reflect off the piezoelectric sensor and return to the observation unit.

“The elapsed time could be used to calculate the distance between the observer and the piezoelectric sensor,” explains Adib. “But, in practice, timing such backscatter is complicated, because the ocean can be an echo chamber.

“The sound waves don’t just travel directly between the observation unit and sensor,” Adib points out. “They also careen between the surface and seabed, returning to the unit at different times. You start running into all of these reflections.

“That makes it complicated to compute the location,” claims Adib. “Accounting for reflections is an even greater challenge in shallow water. The short distance between seabed and surface means the confounding rebound signals are stronger.”

The engineers overcame the reflection issue with “frequency hopping.” Rather than sending acoustic signals at a single frequency, the observation unit sends a sequence of signals across a range of frequencies. Each frequency has a different wavelength, so the reflected sound waves return to the observation unit at different phases.

Adib and his colleagues are now attempting to improve the UBL technology by solving challenges like the conflict between the low bit rate required in shallow water and the high bit rate needed to track movement.

UBL estimated the distance between a transmitter and backscatter node at various distances up to nearly half a meter. The MIT engineers are also working to increase UBL’s range in the field, and they hope to test the system with their collaborators at the Woods Hole Oceanographic Institution on Cape Cod.

“UBL could one day help autonomous vehicles stay underwater, without spending precious battery power,” says Adib. “The technology could also help subsea robots work more precisely, and provide information about climate change impacts in the ocean.”

Engineers at MIT have developed a battery-free pinpointing system that may be used in future unmanned underwater vehicles. Photo courtesy Massachusetts Institute of Technology